In the ever-evolving landscape of product manufacturing, the pursuit of optimal quality and efficiency remains a constant challenge. One technology that has significantly contributed to this endeavor is rapid prototyping. This innovative process has revolutionized the way products are designed, developed, and produced in Saudi Arabia, leading to improved final outcomes and reduced production costs.

Advancements in Rapid Prototyping: A Game-Changer for Saudi Arabian Manufacturers

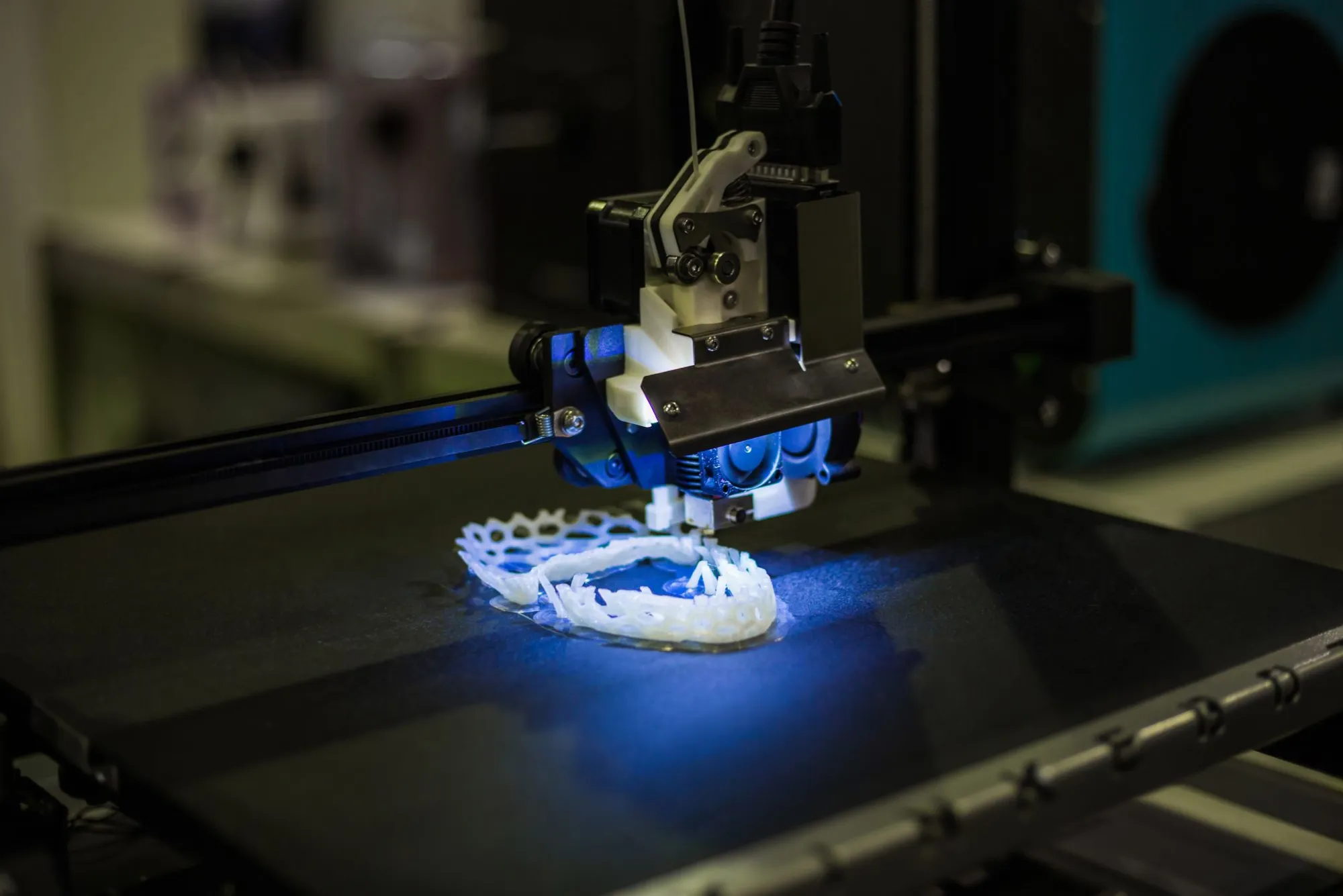

Rapid prototyping technologies such as HordRT have played a crucial role in transforming the manufacturing industry in Saudi Arabia. By allowing manufacturers to quickly create physical prototypes from digital designs, these technologies enable faster iterations and more efficient testing processes. This not only accelerates product development but also reduces time-to-market for new innovations.

Moreover, rapid prototyping empowers manufacturers to identify design flaws or potential issues early on in the development cycle. By simulating real-world conditions through virtual testing methods like Mold Flow Analysis, companies can optimize their designs before investing significant resources into full-scale production.

Furthermore, rapid prototyping offers immense benefits for industries with strict regulations such as aerospace and defense. The ability to rapidly produce functional prototypes allows manufacturers to comply with stringent requirements imposed by organizations like ITAR (International Traffic in Arms Regulations). By thoroughly evaluating prototypes before mass production, companies can ensure compliance while minimizing costly errors or delays.

Rapid Prototyping: Fueling Innovation across Industries

The impact of rapid prototyping extends beyond traditional manufacturing sectors; it has also spurred innovation across various industries within Saudi Arabia. For instance, medical device manufacturers have leveraged this technology to develop intricate and customized devices tailored specifically to patients’ needs.

Rapid prototyping enables medical professionals to create patient-specific models that aid surgical planning, implant design, and medical education. This not only enhances the precision and effectiveness of medical procedures but also contributes to improved patient outcomes.

Unlocking New Possibilities: The Future of Rapid Prototyping in Saudi Arabia

The rapid prototyping industry in Saudi Arabia is poised for significant growth as more companies recognize its potential benefits. With ongoing advancements in materials, software, and hardware technologies, the capabilities of rapid prototyping continue to expand.

In the coming years, we can expect further integration of artificial intelligence (AI) and machine learning algorithms into rapid prototyping processes. This will enable automated optimization of designs based on real-time feedback from virtual simulations or physical prototypes.

Additionally, 3D printing technologies are becoming increasingly accessible and affordable. As a result, small businesses and entrepreneurs within Saudi Arabia can leverage these tools to bring their innovative ideas to life without substantial upfront investments.

Rapid Prototyping: A Catalyst for Progress

The adoption of rapid prototyping has undoubtedly transformed Saudi Arabia’s manufacturing landscape by fostering innovation, improving product quality, reducing costs, and expediting time-to-market. As this technology continues to evolve at an unprecedented pace, it holds immense potential for driving economic growth across various sectors within the country.

By embracing rapid prototyping as a catalyst for progress, Saudi Arabian manufacturers can position themselves at the forefront of global competitiveness while delivering cutting-edge products that meet both local demands and international standards.