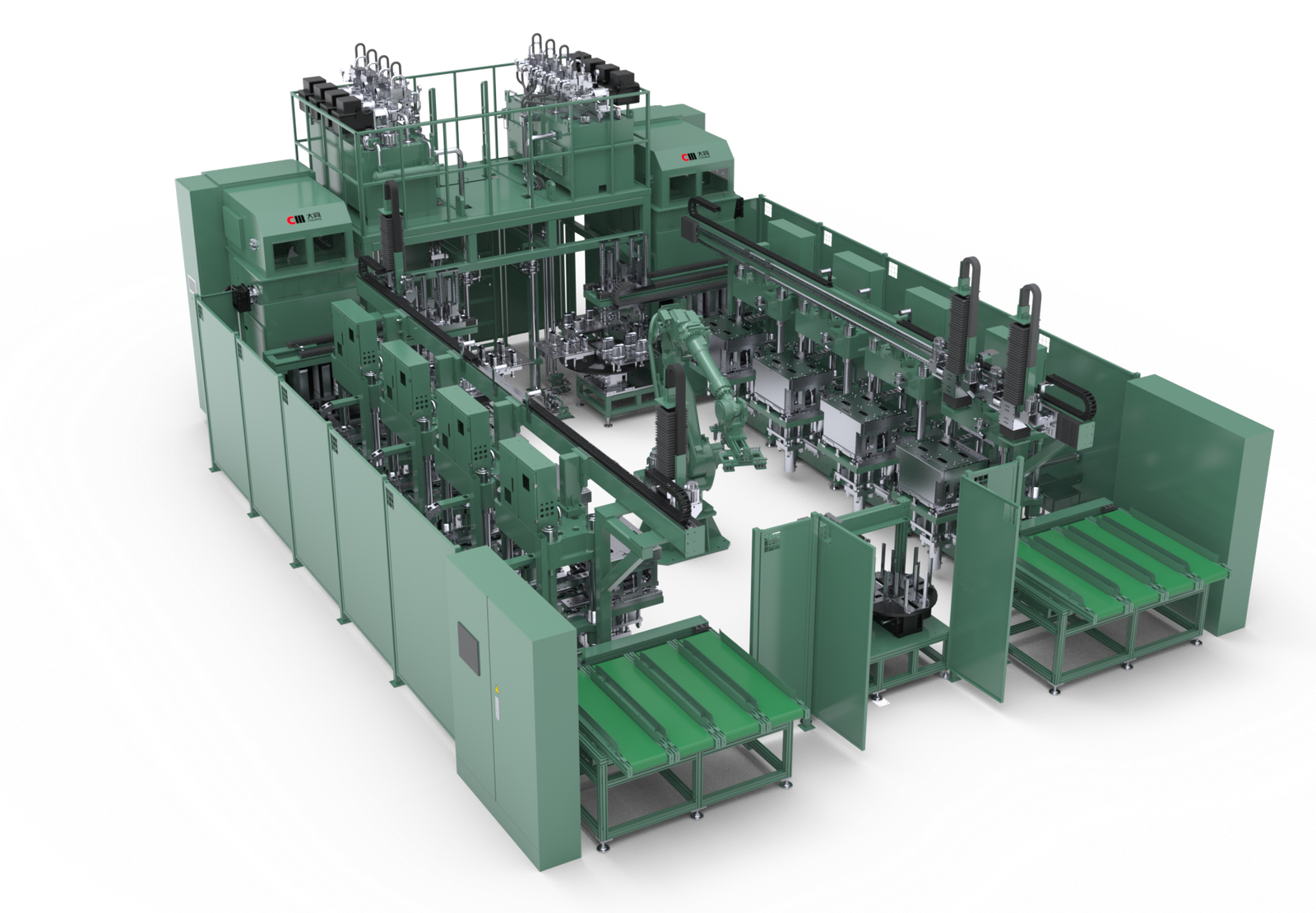

Cosmos Press has developed cutting-edge automated hydraulic press systems that significantly enhance manufacturing efficiency. Their Brake Pad Hot Pressing Automatic Production Line is a prime example of how automation can streamline production processes in the automotive sector.

High-Speed Production

This molding hydraulic press is designed for high-speed operation, achieving a production rate of 12 cycles per hour. With capabilities for both small and large brake pads, it can handle varying sizes and weights, accommodating different production requirements. The multi-station production setup allows for flexible configurations, enabling manufacturers to switch between brake pad models with ease.

User-Friendly Operation

The automated hydraulic press features an intuitive human-machine interface that simplifies the operation process. Operators can easily set parameters and store recipes, making it straightforward to manage production runs. This user-friendly design minimizes the need for extensive training, allowing operators to focus on maximizing production efficiency.

Enhanced Automation for Efficiency

One of the standout features of the Brake Pad Hot Pressing Automatic Production Line is its high level of automation. The system allows for single-operator control of the entire production line, reducing labor costs and increasing per capita output. This streamlined operation is particularly beneficial in a fast-paced manufacturing environment, where efficiency is essential.

Conclusion

In conclusion, the automated hydraulic press from Cosmos Press offers a reliable and efficient solution for brake pad manufacturing. With its high-speed capabilities, user-friendly operation, and enhanced automation, it stands out as a valuable asset for manufacturers looking to optimize their production processes and meet growing demands.